Posted by Butch Owen on Jan 8th 2019

Anatolian Rose Production

This article was originally posted by Butch Owen, founder of AVNP in 2002. We republished this blog in 201. Over the years many have thanked us for the information contained in this article. If you are reading this for the first time you will also appreciate the information and unique writing style that made Butch Owen a favorite on many online groups.

|

Due to a shortage of records and contradictions in many of the available records, ancient history is sketchy - at best. Likewise, the origin of Rosa damascena has been a subject of debate and speculation for many centuries - and research continues. It is generally believed that the Rosa damascena originated in the Neolithic period, in southern Anatolia, as a hybridization of Rosa gallica and Rosa phoenicia, both of which have grown wild in Anatolian Turkey for centuries - and continue to grow wild here today. As early as 3,000 B.C., Anatolia was a land of independent city states and petty kingdoms. Excavation of these ancient sites show that the rulers lived in splendor - mounds of golden ornaments and jewelry attest to the fact that they wanted for nothing. The difficulty of producing Rose oil would not have been an issue for these monarchs. Though there are no credible records for this period and all of these cities were devastated towards the end of the third millennium B.C., there is some evidence that forms of Rose oil was being prepared in Anatolia as early as the 4th century B.C. by macerating Roses in olive oil.

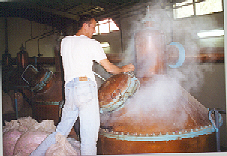

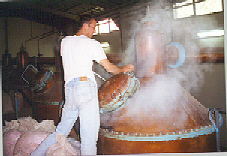

Then came other civilizations - the Mycenaeans, the Hittites and others. All of these civilizations were destroyed and and all memory of them was erased until recently. It was the coming of the Phrygians that left us some history in the form of carved tablets. Such records attest to the fact that Roses were growing in the gardens of Phyrgian King Midas (of the Golden Touch), in Gordion, just outside of Ankara, in 700 B.C. The legends tell of his frustration with the "Golden Touch" when he touched his Roses - among other things - and had them turn to gold. Historians believe the legend began due to the King's desire and ability to acquire massive amounts of the precious metal. King Midas was buried in the largest tumulus ever constructed in this land - over a natural earth energy center. I have taken Rose Otto into that tomb and though I can detect no change in the odor, there are those who swear it is a finer Rose Otto than the other Rose Otto from the same batch produced in the same year .. I make no claims on this and sell it for the same price as the other Rose Otto I offer. If you want to try this Rose Otto - ask me for the Midas Rose Otto. By the 1st century AD, Rose cultivation was common in Turkey. During that period, it is likely that much of the Rose oil was extracted by boiling the Roses and scooping off the oil that floated on the top of the water. I've often read that in those days, Rose oil was considered an impurity and was discarded, but the Turkish professors and historians I have talked with here laugh at that notion. It appears that this tale (speculation) is based on a fantasy that has been passed along from writer to writer until it became a popular rumor. Ottoman documents speak of Gulcus (Rose Oil sellers) and Gulsucus (Rose Water sellers). There are paintings of these colorful peddlers in Ottoman archieves and museums - and colored prints on my desk. The Turkish word for Rose is Gul - the Turkish word for smile is also Gul. Gul and derivations of the word are the most popular names for females in Turkey - I have recorded over 200 and there are many more. Crude distillation of Roses for the oil probably began in Persia in the late 7th Century A.D. By the 9th Century, Rose oil was commonly produced in Persia and the technology began to spread to other places, to include Anatolia, which at the time was occupied by various tribes of Turkic peoples. Records of that period reflect horses being traded for bolts of woven materials and containers of Rose Oil. It was in the 14th Century A.D., after the fall of Byzantium and the conquest of Anatolia by the Ottomans, that a new empire that was to rule for more than 600 years took control of Anatolia and parts of Europe. Production of Rose oil soon spread into the many Ottoman provinces, to include the province of Rumeli (now known as Bulgaria). It is believed that Rose cultivation was introduced to Rumeli by a Bulgarian (Ottoman) merchant in the mid-15th Century A.D. The Turkish word for "still" is Kazan - the areas in Rumeli (Bulgaria) best suited for Rose growing were determined to be Kazanlik (Turkish for "The Place/Location of Stills") and Karliova (Turkish for "Snowy Plain"). In a short time, those two areas became the world center for production of Rose Otto. Of course, the term "Otto" cames from Ottoman (Empire) - as in the modern-day Republic of Turkey. The term Attar is a commonly misused term. It should not be used to describe the oil from Rosa damascena, but too often it is. The word "Attar" originated from the Turkish word "Atir" (undotted "i") - which is pronounced "ahtur." It simply means "sweet-smelling or fragrant". Today, the correct usuage of the word Attar is to describe those oils produced in India that are co-distilled with Sandalwood. It was in the 1880's that modern (for that time) commercial hydro-steam production of Rose Otto began in the area of the Ottoman Empire that is presently the Republic of Turkey. Following the fall of the Ottoman Empire and the rise of the new Republic of Turkey, the founder, Mustafa Kemal Ataturk, began to push rapid modernization and commercialization and in the early 1930s, he created the modern Rose Otto production center in Isparta, Turkey .. an area that is often referred to as the Rose Fields of Turkey. We must be careful to avoid becoming victims of the misinformation and disinformation concerning production of Rose Otto. We can read where the center of Rose Otto production is still Bulgaria, but today Bulgaria produces far less Rose Otto than does Turkey. It is likely that this rumor is based on writers refusing to update their ancient references, a problem common in the cottage-industry of aromatherapy. As stated herein, Bulgaria was once the world center for production of Rose Otto but Bulgarian production began a decline during and following World War II and the rise of the Communist regime. In June on this year, I read a newly released report from Mr. P. Tardy of the World Bank, on the production of Rose Otto. This report stated that 75% of the world-wide production of Rose Otto is produced by Turkey and that 65% of the Rose Otto produced in Turkey is produced by the Rose Growers Association (RGA). I have personal knowledge that private Rose Otto producers in Turkey frequently make large purchases of Rose Otto from the RGA. As for Bulgarian Rose Otto, if one finds a good Bulgarian Rose Otto, the quality will be similar to that of the Turkish Rose Otto .. however, the fall of the Communist regime in Bulgaria created a power vaccum in the administration and control of many Bulgarian industries. This vaccum was quickly filled by elements that operate in a manner that creates a need for buyers to exercise caution when purchasing Bulgarian products. Find a proficient, honest Bulgarian Rose Otto distiller and you'll get a fine product .. but Caveat Emptor! There are two forms of Turkish Rose oil distillation, the traditional but slowly disappearing village-type distillation using log-fired crude stills known as "Imbeks" and the modern factory production method using hydro-steam distillation in stills called "Kazans." Both forms have distinctive characteristics, but the quality Turkish Rose Otto is the factory produced oil - there are no differences of opinion on this. In Part I, you saw factory production photos - I don't have photos of a village production operation but I'll describe it. For centuries, the villagers loaded roses into crude copper open-fire stills that consist of a retort and a head. The head is removable and spherical in shape. It's connected to a pipe which is laid through a pool of water to cool the condensate. This is the simplest form of distillation and produces a lower percentage of oil, but some nice hydrosols. Controlling the temperature is next to impossible as many of these stills are over open fires. Those of you who have made the Annual Rose Pilgrimage to Turkey have seen such stills (Imbeks) in the hallways of the RGA Headquarters. The citronellol content of village-type produced oils is lower than that of the commercially produced, hydro-steam distilled oils and often one can detect a "burned" odor in the village-cooked oil. Even the odor of commercially produced, hydro-steam distilled Rose Otto can vary from company to company .. this is due to slight variations in the chemical composition of the final product which can be caused by a number of factors during the collection and distillation of the Rose blossoms. The master distiller (Usta) employed by the Rose Growers Association has worked in the trade for over 47 years (since 1954) and there is a consistency of quality in the Rose Otto produced there. He is recognized in Turkey as THE EXPERT on production of Rose Otto! There appears to be a Rose Otto producer - or perhaps a wholesaler - who is telling resellers that their Rose Otto is produced from a "single crop" of Roses. This is pure bovine excrement - no such thing exists - the notion is somewhere between fantasy and fraud. Continuation of this fantasy shows a lack of understanding of the reality of Rose cultivation in Turkey. If you hear or read of someone claiming to sell a Turkish Rose Otto that was produced from a "single crop" of Roses, you should consider the following: 1. Someone is playing with words or repeating the marketing hype fed them by the source of their Rose Otto. Why would a source give out such erroneous information? To make their product sound special! The only thing missing is a claim of the Roses only being harvested by virgins between the ages of 14 and 16, each being at least a "9" on a 1 to 10 beauty scale, and each wearing a white silk gown while chanting Hari Krishna and praying for forgiveness for each Rose blossom picked. 2. The information is incorrect because:

Distillation of Rose Otto from a single crop is just not a reality. I didn't make up these facts and figures - that's just the way it is. If you read information contrary to the above, it is false information! 3. The information is unnecessary because:

One publication recently stated that it takes between 2 and 4 tons of Rose blossoms to produce a kilogram of Rose Otto. There has never been a kilogram of Rose Otto produced with less than 3,500 kilos of Rose blossoms! Another rumor that we must watch for is that fresh Rose Otto is better than aged Rose Otto - its just not true! The odor of Rose Otto improves with age. If you want to do a nose test for yourself, I can supply you with a gram of Rose Otto from crops distilled in 1997, 1998, 1999, 2000 and 2001. Due to similarity of chemical composition of the product, this is true for Bulgarian and Turkish Rose Otto, however, one is not likely to easily find any aged Bulgarian Rose Otto. The need for cash forces most producers (Turkish and Bulgarian) to sell their product the same year it is produced - mostly to perfumeries and often at slightly reduced prices. It is only the large Co-Ops that have the financial capability to sit on millions of dollars of Rose Otto. Each year, the Rose Growers Association produces a bit more Rose Otto than they plan to sell in that year - and I like that! For the new folks who have just started dabbling in essential oils, I'll say that the cottage-industry of aromatherapy has a foundation based on rumor/misinformation/disinformation and marketing hype. If not for all of this it might be boring. Without these distractions, one could get the same training from any teacher, read the same facts in any reference publication and decisions on which seller's essential oils one should purchase would be narrowed down to points of price and proof of quality. Take away all the intrigue and narrow the issues down to facts that are mutally agreed upon and the only thing left are the esoteric issues. ;-) |

||

Photo 19: The Rose oil separating from the oil-bearing water in this photo of the first distillation is known as "Crude Oil, First Oil, Raw (Chi) Oil or Direct Oil". It's thick, dark, highly concentrated and very valuable but it's not sold in this state; it will later be blended with the Rose oils from the second distillation (the cohobation). This "Crude Oil" makes up approximately twenty percent of the total volume of oil that will be rendered from that distillation. The remaining eighty percent will be recovered from the second distillation of oil-bearing waters in a process called "cohobation." Photo 20: This is the Crude Oil after filtering. It's kept in glass flasks and then blended with the oils from the second distillation (cohobation) to produce the final product - Anatolian Rosa damascena. | ||

Photo 21: The oil-bearing water from the first distillation (of the Rose blossoms) is pumped into these large tanks to be held until it goes through the second distillation (cohobation). The cohobation is performed in a separate still maintained for that purpose only. Contrary to what we read in some books, the oil-bearing waters ARE NOT recycled through the spent Rose blossoms. There would be no purpose in doing this as the Rose blossoms have given up all the oil they will give during the initial distillation. The cohobation is only to extract the lion's share (around 80%) of the remaining Rose oil from the oil-bearing water. Photo 22: Rose oil extracted from the second distillation (cobation) of the oil-bearing waters is called "Second, Indirect and/or Recovered Oil." I prefer to call it Liquid Gold! In this photo, the golden colored liquid at the top of the Florentine Flask (cylinder) is Rose oil - that underneath is oil-bearing water - it is the Rose Hydrosol. There's a dump valve in the center of the Flask - when the level of Rose oil rises to the top of the valve, it spills over and escapes through this tube/valve into a glass holding bottle. A small amount of the water will also escape. The master distiller (Usta) will later remove that water using a hose and suction - like siphoning gasoline from your car. After blending of the first and second oils, the final product, the Anatolian Rose Otto, is packed in tinned steel containers called "Kumkuma" - these containers look like US Civil War canteens. They are the containers that those of you who have purchased Turkish Rose Otto in bulk have fought to open - until you figured out that it was a very easy task .. ;-) |